Automatic Fast Food Box Making Machine

Sample:

Working Principle:

Technical Parameters:

Summary of Machine:

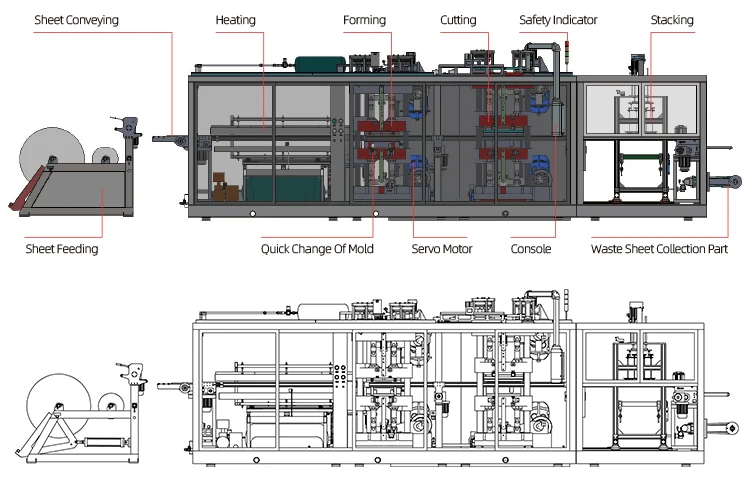

1.Every station is driven by the eccentric crank linkage structure.

2.Feeding and heating part have optoelectronic switch in order to prevent error operating from production process.

3.The toothed chain made of 65#Mn, helping convey sheet. Aluminum rails with water cooling, save water.

4.The machine adopts PID temperature system, it shows high precision, and temperature control tolerance <1℃.

5.Each servo motor has overload protection for machine’s overworking.

6.Low barycenter and height of finished products as well as steady running ensures easy operation and friendly viewing.

7.There is an alarm function of the sliding doors.

Company Brief Introduction

Litai Machinery CO., LTD was founded in 2001. For more than 20 years, we focus on researching, developing, manufacturing and marketing on thermoforming machine, plastic cup production line, BOPS plastic thermoforming machine, full automatic high quality fast food box making machine used for packaging sweets and pizza box thermoforming machine, single-layer PP/PS sheet extruder, mould, etc. There are more than 79 countries and regions cooperating with us, such as USA, south Korea, Turkey, Canada, Russia, Kuwait, Iran, Brazil, Chile, Bolivia, Saudi Arabia, Peru, etc.

Having been involved in designing and manufacturing machines for several years, we have employed experienced designers and have built a high-qualified technical team. We are one of the enterprises that have passed ISO9001 international quality management system in China. Now we are handling production strictly conforming to these standards and supplying high quality products at competitive prices.

Hot Tags: Automatic Fast Food Box Making Machine, China, suppliers, manufacturers, factory

You Might Also Like

Send Inquiry